CONTACT & STAFF

For more information on this beamline, contact us.

The XRD1 beamline is an experimental facility dedicated to X-ray powder diffraction analysis in the hard x-rays energy range (5.5 to 14 keV). It focus on the determination of structural parameters of polycrystalline samples, with applications to physics, chemistry, materials science, materials engineering, geosciences, pharmacy, biology, etc. It is also possible to study the samples in a large range of temperatures (100 – 1070 K).

XRD1 is operational since 1998 and installed on a 1.67 T bending magnet. Recently, the beamline was upgraded and its commissioning is entirely performed. The XRD1 beamline has two experimental stations since 2010. The second experimental station consists of a facility built around an advanced thermo-mechanical simulator, the Gleeble®Synchrotron system, which allows the material of interest to be subject to a wide range of thermo-mechanical conditions.

The first experimental station was built in 1997. With the upgrade process, the old diffractometer was replaced by the 3-circle heavy-duty diffractometer from Newport®. Furthermore, the installation of the MYTHEN 24K system, from Dectris®, and a robotic arm sample changer allowed relatively fast X-ray powder diffraction measurements. The measurement times vary typically between 30 and 400 seconds, depending on the sample and the investigation aims.

Applications include the determination of the lattice parameters of polycrystalline materials as a function of the temperature, resonant X-ray diffraction from K-edge of vanadium to K-edge of bromine and from L3-edge of cerium to L3-edge of polonium, and in-situ experiments with powder and liquid samples.

For more information on this beamline, contact us.

Português:

Difratômetro (3-circle) na Linha de Luz XRD1.

English:

The 3-circle diffractometer at XRD1 beamline.

Português:

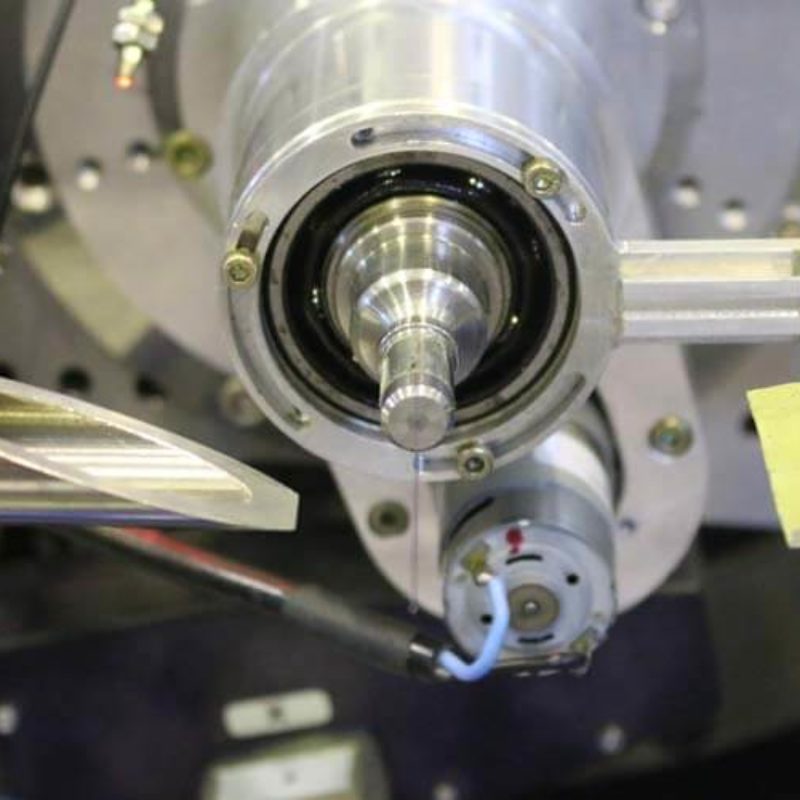

Capilar montado em um suporte de aço inoxidável ferromagnético conectado ao Difratômetro.

English:

A capillary mounted in a ferromagnetic stainless steel holder, which is attached to the 3-circle diffractometer.

Português:

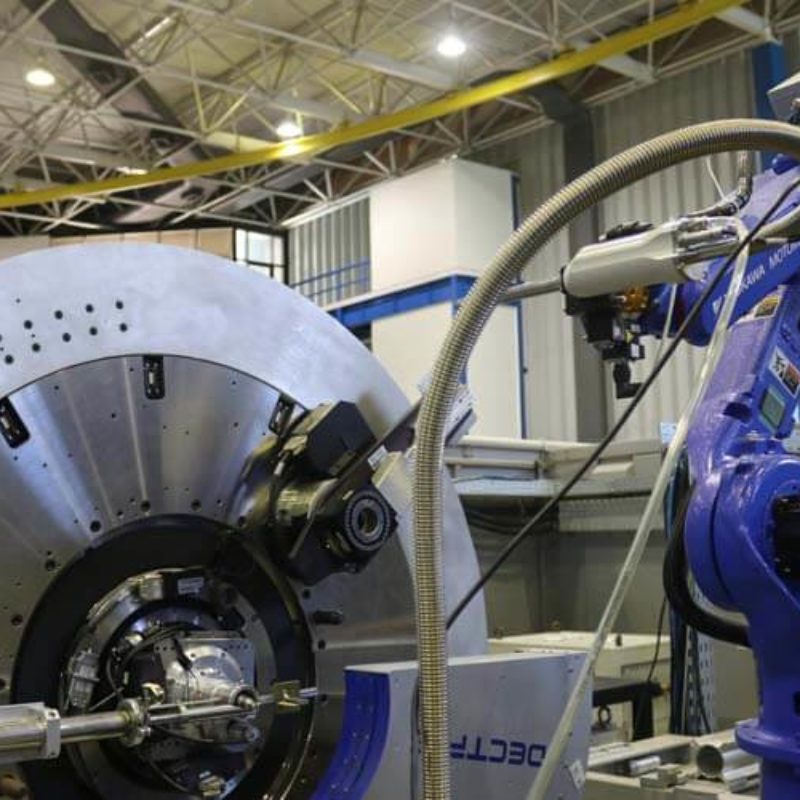

Difratômetro (3-circle) à esquerda e braço robótico segurando o sistema de criojet à direita.

English:

The 3-circle diffractometer (on the left) and the robotic arm holding the Cryojet system (on the right).

Português:

Mesa de amostras usada para acomodar as amostras que serão automaticamente carregadas pelo braço robótico.

English:

Sample table used to arrange the samples that are automatically changed by the robotic arm.

The following experimental techniques and setups are available to users in this beamline. To learn more about the techniques’ limitations and requirements (sample, environment, etc.) contact the beamline coordinator before submitting your proposal.

The XRD1 beamline is optimized for structural characterization by X-ray diffraction experiments in Debye-Scherrer geometry, i. e. transmission mode of low absorption materials. Besides, XRD1 is able to obtain high-quality data for high-absorption materials. It is possible to change the energy to perform resonant X-ray diffraction from K-edge of vanadium to K-edge of bromine and from L3-edge of cerium to L3-edge of polonium. The XRD1 beamline is equipped with two different devices to perform X-ray powder diffraction as a function of the temperature (from 100 K to 1070 K). The beamline is also equipped with a capillary cell, which is used for experiments with powder and gas flux or with liquids.

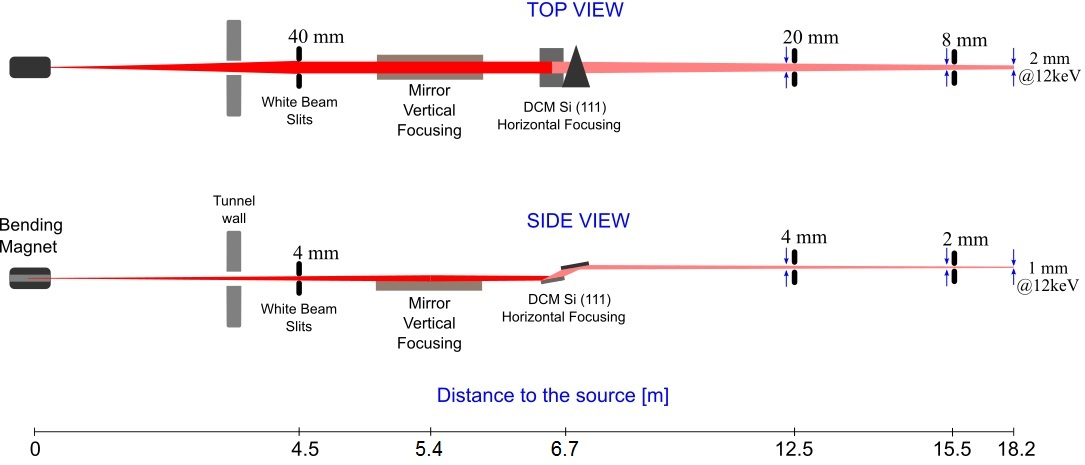

| Element | Type | Position [m] | Description |

|---|---|---|---|

| SRC | Bending Magnet | 0.0 | Bending Magnet D12 exit A (4°), 1.67 T |

| FE | Front-end | – | – |

| S1 | White Beam Slits | 4.5 | Water-cooled |

| M1 | Vertical Focusing Mirror | 5.4 | Rh coated |

| DCM | Double Crystal Monochromator | 6.7 | Si(111) |

| S2 | Slits | 12.5 | – |

| S3 | Slits | 15.5 | – |

| ES | Experimental Station | 18.2 | – |

| Parameter | Value | Condition |

|---|---|---|

| Energy range [keV] | 5.5-14 | Si(111) |

| Energy resolution [ΔE/E] | 3 x 10-4 | Si(111) |

| Beam size at sample [mm2, FWHM] | 2.0 x 0.7 | at 12 keV |

| Vertical Beam divergence at sample [µrad, FWHM] | 116 | at 8 keV |

| Flux density at sample [ph/s/mm2] | 2.4 x 1010 | at 8 keV |

| Instrument | Type | Model | Manufacturer | Specifications |

|---|---|---|---|---|

| Diffractometer | 3 circle | N3050-P1 | 2θmax = 150º | Newport |

| Detectors | Linear | Mythen24K | 50 µm pixel 24 modules | Dectris |

| Cryojet | Cooler and Heater | CryojetHT | 100 – 450 K at sample | Oxford Instruments |

| Gas Blower | Heater | GSB1300 | RT – 1070 K at sample | FMB Oxford |

| Capillary Cell | – | – | Use capillaries with diameters up to 2 mm | LNLS in-house development |

All beamline controls are done through EPICS (Experimental Physics and Industrial Control System), running on a PXI from National Instruments. The data acquisition is done using a Red Hat workstation with the Py4Syn, developed at LNLS by SOL group. CSS (Control System Studio) is used as a graphical interface to display and control the beamline devices.

Users are required to acknowledge the use of LNLS facilities in any paper, conference presentation, thesis and any other published material that uses data obtained in the execution of their proposal.

A. M. G. Carvalho, D. H. C. Araújo, H. F. Canova, C. B. Rodella, D. H. Barrett, S. L. Cuffini, R. N. Costa, R. S. Nunes, X-ray powder diffraction at the XRD1 beamline at LNLS, J. Synchrotron Rad. 23, 1501-1506 (2016). DOI: 10.1107/S1600577516012686

Various upgrades have been completed at the XRD1 beamline at the Brazilian synchrotron light source (LNLS). The upgrades are comprehensive, with changes to both hardware and software, now allowing users of the beamline to conduct X-ray powder diffraction experiments with faster data acquisition times and improved quality. The main beamline parameters and the results obtained for different standards are presented, showing the beamline ability of performing high-quality experiments in transmission geometry. XRD1 operates in the 5.5-14 keV range and has a photon flux of $\rm 7.8 \times 10^{9} photons.s^{-1}$ (with 100 mA) at 12 keV, which is one of the typical working energies. At 8 keV (the other typical working energy) the photon flux at the sample position is $\rm 3.4 \times 10^{10} \rm photons.s^{-1}$ and the energy resolution $\rm \Delta E/E = 3 \times 10^{-4}$.

Scientific publications produced with data obtained at the facilities of this beamline, and published in journals indexed by the Web of Science, are listed below.

Onna, D. A.;Ricci, M. L. M.;Bilmes, S. A.;Marchi, M. C.. Loading insoluble sulfides in mesoporous oxide films from precursors in solution, Journal of Sol-Gel Science and Technology, v.102, p.264–278, 2022. DOI:10.1007/s10971-021-05718-4

Darabian, L. M. ;Gonçalves, G. dos R.;Schettino, M .A.;Passamani, E.;Freitas, J. C. C.. Synthesis of nanostructured iron oxides and study of the thermal crystallization process using DSC and in situ XRD experiments, Materials Chemistry and Physics, v.285, p.126065, 2022. DOI:10.1016/j.matchemphys.2022.126065

Fonseca, R. O. de ;Ponseggi, A. R. ;Rabelo Neto, R. C.;Simões, R. de C. C. ;Mattos, L. V.;Noronha, F. B.. Controlling carbon formation over Ni/CeO2 catalyst for dry reforming of CH4 by tuning Ni crystallite size and oxygen vacancies of the support, Journal of CO2 Utilization, v.57, p.101880, 2022. DOI:10.1016/j.jcou.2021.101880