Research investigates effect of additive manufacturing on aerospace materials

Aerospace vehicles – airplanes, helicopters, rockets, spacecraft, satellites and others – are subject to extreme conditions of temperature, pressure and mechanical load during their operation. Thus, materials and manufacturing methods used in the aerospace industry are constantly evolving, always seeking increased reliability and weight reduction without sacrificing mechanical performance. An important class of materials for the aerospace industry is the Maraging steel. They feature high mechanical strength and are used in components such as landing gear for airplanes or helicopters and even rocket fairing, which are subjected to high mechanical loads and fatigue cycles.

Additive manufacturing – popularly known as 3-D printing – has revitalized the manufacture of components with shapes previously considered challenging, or even impossible, and increased the potential for use of different engineering materials. However, although the structure and chemical composition of a given material is known, the product obtained in the additive manufacturing process is fundamentally different from what is obtained by conventional manufacturing processes such as casting or welding.

The very high heating and cooling rates of the additive manufacturing process result in materials with inhomogeneous distributions in their microscopic composition and structure that cannot be easily predicted through computational models. As the mechanical properties of materials depend directly on these microstructures obtained after the manufacturing process, it is necessary to understand the origin and evolution of these new structures.

Therefore, Fábio F. Conde et al. [1] sought to understand how the structure and properties of Maraging steels are modified by the additive manufacturing process. To this end, the group conducted an in-situ study of the crystallographic evolution in Maraging 300 steel parts produced by this method.

In the study, the XTMS experimental station associated with the XRD1 X-ray diffraction beamline of the Brazilian Synchrotron Light Laboratory (LNLS) was used. This station allows obtaining crystallographic information during the application of a wide variety of thermal and mechanical conditions. According to the researchers, the station is of vital importance for the optimization of these materials and for understanding the advantages, disadvantages and limitations of the additive manufacturing technique for the aerospace industry.

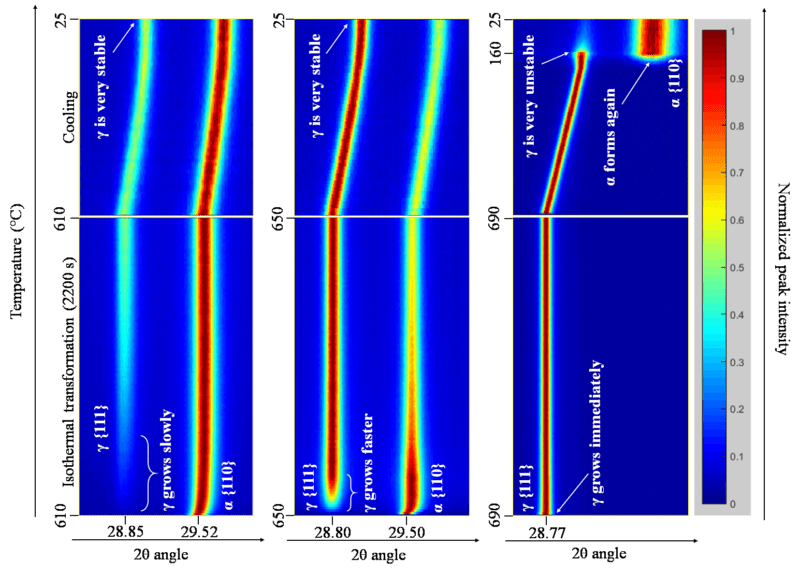

During manufacture, formation of the austenite phase ($ \gamma $) in the martensite matrix ($ \alpha $) is desired as it is partly responsible for the ductility of steel. In-situ analyzes were performed during tempering – applied to steel to correct excessive toughness and hardness – at 610, 650 and 690°C for 2200s, followed by cooling to room temperature, as summarized in Figure 1.

Increasing tempering temperature allows the formation of the $ \gamma $ phase to be faster, and the total amount produced to increase. However, excessive temperatures, such as 690°C, cause excessive formation of the $ \gamma $ phase and result in unwanted transformation of $ \gamma $ into $ \alpha $ during cooling to around 160°C.

Figure 1: X-ray diffraction peak intensity map as a function of time. Tempering heat treatments were simulated on the XTMS station using tempering temperatures of 610, 650 and 690°C for 2200s, followed by cooling cycles to room temperature. Adapted from [1].

Source: [1] F.F. Conde, J.D. Escobar, J.P. Oliveira, A.L. Jardini, W.W. Bose Filho, J.A. Avila, Austenite reversion kinetics and stability during tempering of an additively manufactured maraging 300 steel, Additive Manufacturing 29 (2019) 100804. DOI: 10.1016/j.addma.2019.100804.

Results may contribute to a better understanding of the chemical reaction that causes the degradation of concrete structures

Research investigates the concentration of chemical elements in commercial species