The beamline is dedicated to three-dimensional tomographic imaging with micro and nanometric resolution using high brightness X-rays in the energy range of 22, 39 and 67 keV

MOGNO is one of the beamlines of the Sirius synchrotron light source, of the Brazilian Center for Research in Energy and Materials (CNPEM), a private non-profit organization under the supervision of the Brazilian Ministry of Science, Technology and Innovations (MCTI).

The facility is dedicated to obtaining three-dimensional tomographic images with micro and nanometric resolution. Internal structures of various materials can be studied non-invasively, at different spatial resolution, ranging from hundreds of nanometers to tens of micrometers. In addition, it will be possible to subject materials to different mechanical, thermal, or chemical conditions and monitor changes in real time.

Thus, MOGNO will enable detailed studies of complex phenomena such as the passage of fluids through the pores of pre-salt rocks, as well as the in-vivo interaction of roots with soils and the non-destructive study of fossils, among others.

MOGNO is designed to be a micro and nano imaging beamline using quasi-monochromatic (ΔE/E ~ 10-2) high brightness hard X-rays (22, 39 and 67 keV). This design is optimized to perform continuous zoom tomography (i.e., continuous image magnification), in which the same specimen can be studied at low and high resolution. MOGNO will also be dedicated to the acquisition of 4D (time-resolved) images from in-situ and in-operando experiments.

The primary source of the beamline is a high-field (3.2T) permanent dipole (BC), that produces hard X-rays with a critical energy of 19.5 keV and a beam size of 22.1 x 8.5 mm2 (HxV, rms). The beam is demagnified to a nanometer focal spot (approx. 120 x 120 nm2) using a set of three elliptical mirrors, which introduces a divergence and thus the beamline operates in a cone-beam geometry with variable field-of-view (FOV between 150 x 150 µm2 and 85 x 85 mm2) and spatial resolution (approx. 120 nm to 55 µm). These conditions are achieved with two experimental nano- and microtomography stations. A high-Z photon-counting detector, with a detection area of about 85 x 85 mm2, will serve both stations. Additionally, the beamline will also feature an indirect detection system based on an sCMOS camera and a macroscope.

The optical system of the beamline has been optimized to achieve high flux at high energy with a narrow bandwidth. After the front-end, the first optical element is a horizontal elliptical mirror (M1) designed to collect the radiation from the BC, demagnify it horizontally, and generate a secondary source for MOGNO’s next optical system, which consists of a Kirkpatrick-Baez (KB) type mirror system. The KB is composed by two elliptical mirrors (horizontally, HFM, and vertically, VFM, focusing), where each one is covered with two multilayers, and are responsible for selecting energies and focusing the beam in a 120 x 120 nm2 region.

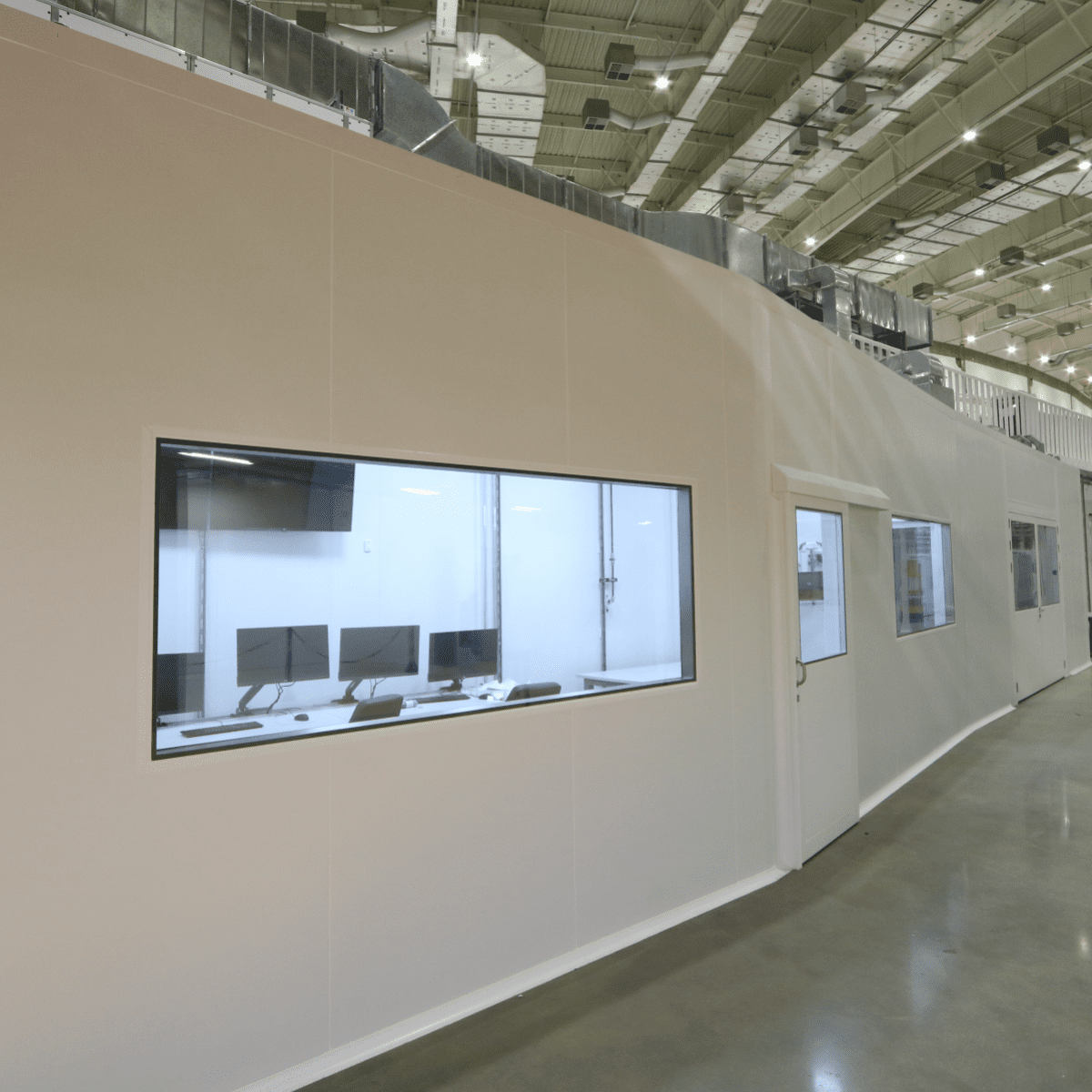

In November 2021, the M1 mirror was installed in the optical hutch, along with the internal diagnostic equipment for secondary source characterization (Figure 1). On December 8, the M1 mirror received the beam for the first time, and on the same day the beam reached the experimental hutch. Currently, issues related to the control of the M1 diagnostic system are being investigated.

Figure 1: (a) M1 assembled at MOGNO’s optical hutch, (b) M1’s internal diagnostic system.

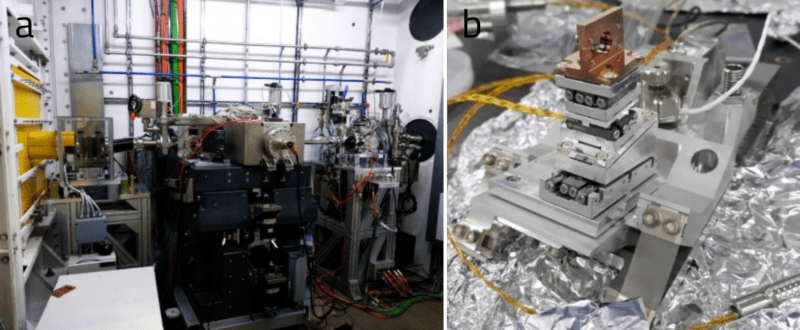

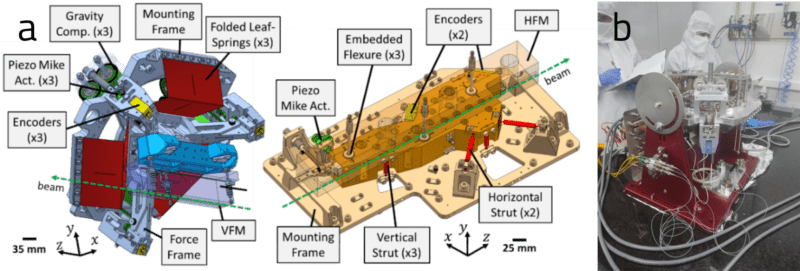

The KB mirror was received and accepted by the LNLS Optics group after figure validation by Fizeau Interferometry (FZI). The KB mirror mechanisms take the same precision engineering and mechanical determinism concepts as Sirius’ other mirror systems, with movement accuracy and position stability on the order of nanometers. The mechanism supporting the VFM has extra degrees of freedom in vacuum allowing toggling the multilayer matching of the VFM to the HFM for energy selection in the MOGNO beamline (Figure 2).

Figure 2: (a) VFM and HFM internal mechanisms with key design features highlighted and (b) VFM mechanism being tested in the cleanroom of the metrology building.

VFM’s mechanism test phase was completed with a short delay due to components of the gravity compensation system arriving out of specification, requiring assembly corrections and further testing to confirm performance. The motion kinematics and control architecture are also in the final stages of testing and validation, releasing the mechanisms for assembly and alignment within the vacuum chamber.

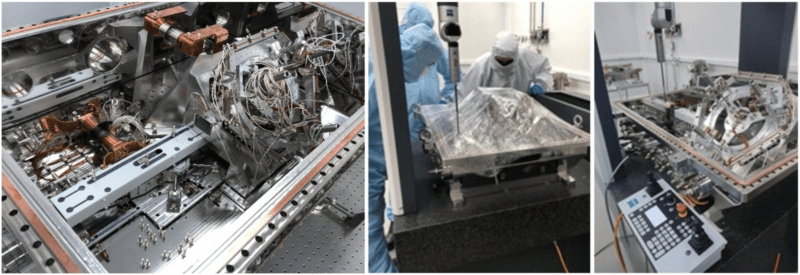

Because of the power absorption due to the monochromatization of the X-ray beam, each of the mirrors has a peltier cooling system to stabilize the temperature during operation (Figure 3). Once the alignment and on-air testing phase is completed, the vacuum chamber will be sealed for a final stage of testing and validation in vacuum before transport to Sirius and the installation and final vacuum conditioning (baking) inside the experimental hutch.

Figure 3: VFM and HFM mechanisms with the peltier cooling system parts mounted in the KB vacuum chamber (left). Mounting the system on the Coordinate Measurement Machine (CMM) (center), and starting the alignment procedure and validating the motion kinematics (right) in the cleanroom of the metrology building.

Installation of the KB in the experimental hutch is expected for early July 2022, followed by alignment, baking, control, and motion validation. Commissioning of the nanostation is expected to begin in early August 2022.

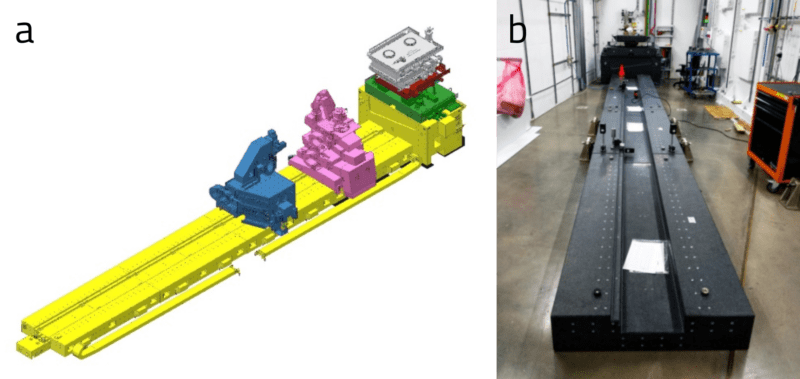

The nanostation is currently in the process of being assembled, with the installation of the KB rail and main base (Figure 4a, in yellow and green, and 4b). Completion of this installation and alignment, including the sample base (in pink) and the detector base (in blue), was concluded in early May 2022. The next steps are related to the system for moving and controlling all the granite pieces, and is scheduled for delivery in late July 2022.

Figure 4: (a) 3D view of the nanostation and (b) picture of the installation inside the experimental hutch.

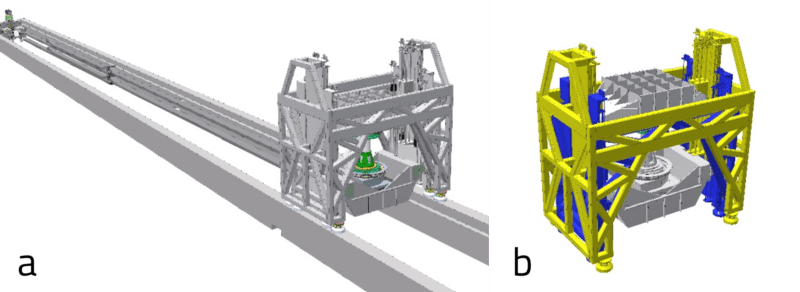

The microstation concept has already been reviewed by a consulting firm, resulting in a few design adaptations to ensure that the system’s performance is compatible with future sample setups, planned for in-situ and in-operating experiments, with fast rotation and heavy loads (approx. 30kg). The project was divided into three parts: main car, gantry and rail (Figure 5). The staff is currently working on detailing the 3D design of the main car, and the assembly tools and strategies are the next phase to be addressed. Installation should begin in the first semester of next year.

Figure 5: (A) 3D view of the microstation and (B) a detailed view of the gantry, which will serve the microstation and receive the complex in-situ and in-operando setups.

The procurement process for MOGNO’s main detector began in late March 2022. After evaluating all commercial possibilities, a decision was made to purchase a PiMega 135D with CdTe sensor. Delivery is expected for early 2023.

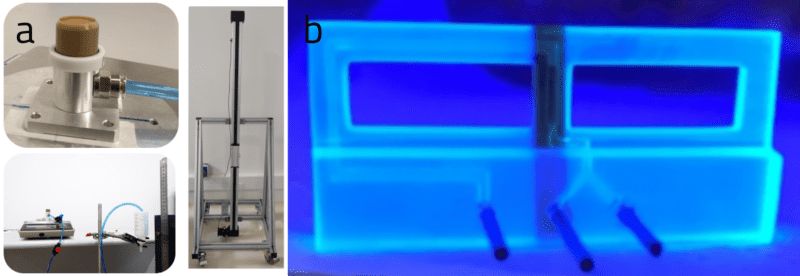

The beamline staff also developed a sample environment that is an adaptation of a traditional experiment to evaluate soil water retention (Figure 6a). The major advantage of this in-situ experiment is visual access to the soil drainage, with controlled pore sizes from the suction pressures that will be applied. The cell has already been validated and is ready for use in the beamline.

Another sample environment under development (Figure 6b) will allow investigation of biomaterials’ behavior under different experimental conditions, in the presence of cells, for instance, or even mimicking inflammatory processes with very high environmental control.

Figure 6: (a) Soil water retention setup and (b) Microfluidic chip for biological setups

Since MOGNO is still in the installation phase, it is not receiving users. However, the Beamline staff offers online courses on image analysis, allowing current and future users to learn how to best handle and process the obtained data.

Currently four image processing courses are available, covering theoretical concepts of digital image processing and analysis; concepts of machine learning and deep learning; and the use of Avizo, a software program widely used by the tomography community, including basic processes such as visualization, filtering, manual and semi-automatic segmentation techniques, data quantification, and animation features.

This support laboratory allows the preparation of advanced samples and their characterization using electron and optical microscopy techniques, complementary to the experiments in the beamlines

New commissioning stage of Imbuia beamline allows the use of advanced infrared spectroscopy techniques at micro and nano scales