CONTACT & STAFF

Facility E-mail: sape@lnls.br

Coordination: Wendell S. E. Silva

Tel.: +55 19 3512 1042

E-mail: wendell.silva@lnls.br

Click here for more information on this Facility team.

SAPÊ (Angle-resolved PhotoEmission) is a beamline dedicated to angle-resolved photoemission spectroscopy (ARPES) experiments, with high energy and momentum resolution, in the vacuum ultraviolet (VUV) spectrum range. Such experiments allow the analysis of the electronic structure of crystalline materials and are an essential tool for the study of the frontier of new materials, with special emphasis on topological materials and 2D materials.

The experimental endstation of the beamline has a set of a ultra-high vacuum (UHV) chambers through which the samples will be loaded, handled and prepared before the ARPES experiments. The main objective of the SAPÊ beamline is to provide the Brazilian scientific community with a tool capable of probing the band structure of new materials and unveiling phenomena that may arise from it.

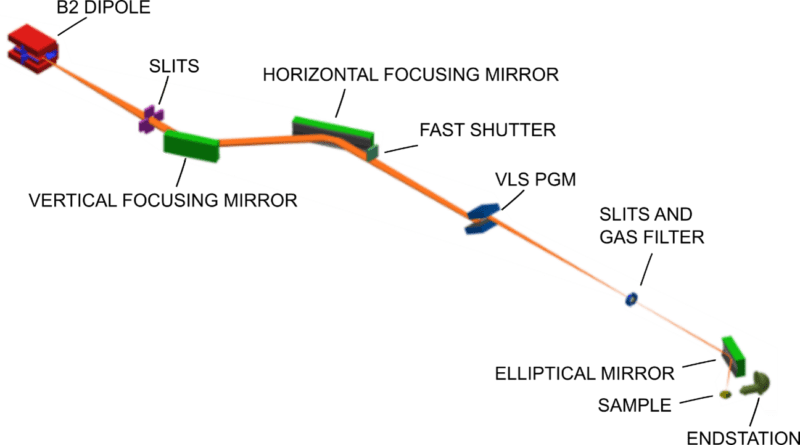

The UV extraction is done from a B2 dipole and provides a photon flux, in the sample, of up to 1×1012 ph/s/100mA at 40 eV and a resolving power of > 10,000 at 10 eV. The operating energy range of SAPÊ is between ~ 8 and 70 eV and the micrometer beam in the main chamber will allow carrying out ARPES experiments with high energy and momentum resolution on ~20×20 μm2 samples.

Facility E-mail: sape@lnls.br

Coordination: Wendell S. E. Silva

Tel.: +55 19 3512 1042

E-mail: wendell.silva@lnls.br

Click here for more information on this Facility team.

| Element | Type | Position [m] | Description |

|---|---|---|---|

| Source | Bending Magnet | 0.0 | Dipole B2 0.56 T |

| M1 | Vertical Focusing Mirror | 10.60 | Silicon |

| M2 | Horizontal Focusing Mirror | 14.10 | Silicon |

| Grating | Monochromator | 22.22 | VLS PGM |

| M3 | Elliptical Mirror | 33.19 | Silicon |

| Parameter | Value | Condition |

|---|---|---|

| Energy range [eV] | 8 – 70 | VLS-PGM |

| Energy resolution (ΔE/E) | 10.000 | Slit selection and cff on the VLS-PGM |

| Photon flux [phs/s/100 mA] | 1×1012 | Slit selection and cff on the VLS-PGM |

| Beam size [μm2] | 20×20 | Slit selection and cff on the VLS-PGM |

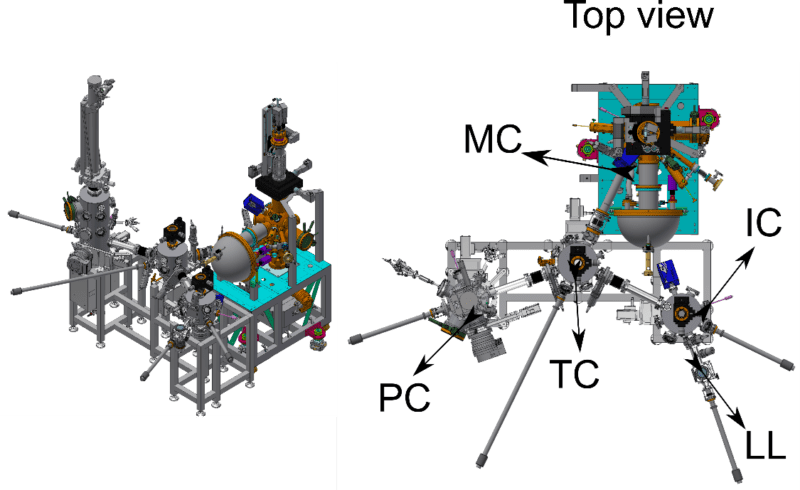

The experimental endstation of SAPÊ beamline has 5 chambers in an UHV environment. The chamber where the ARPES experiments are carried out is the main chamber (MC); it contains a SPECS PHOIBOS 150 spectrometer and a CARVING manipulator with a cryostat. There are 4 more chambers attached to the MC, one of them being the sample preparation chamber (PC), which has a manipulator with 4-axis movement and a heating which can go up to 1000K, N2L cryostat, a LEED optics, an ion source and two e-beam evaporators. There are two more chambers, the transfer chamber (TC) and the introduction chamber (IC), which are responsible for maintaining the UHV environment during sample transferring from PC to MC and during sample loading into the system, which is done in the load lock chamber (LL).

The SAPÊ experimental station is dedicated to high-resolution ARPES experiments. In the main chamber it will be possible to perform measurements of the band structure of micrometric samples with high resolution in moment and photoelectron energy. These measurements will be made after the beam hits the sample fixed in the manipulator and cooled by the cryostat inside the MC. The Manipulator has 6 axes of motion (3 rotations and 3 translations) that will assist with alignment and angular scanning during data acquisition. The photoelectrons will be detected by the MCP of the analyzer installed in the MC, and the photoemission spectrum is sent to the computer by a CCD SensiCam câmera.

| Element | Parameter | Value |

|---|---|---|

| Carving manipulator | Motion

Cooling [K] |

6 axis

~ 16 – 300 |

| PHOIBOS 150 spectrometer | Resolution ΔE [meV]

Resolution Δθ |

< 2

< 0.1° |

| Sample environmental | 1×1012 | < 6×10-11 |

| Samples | Type

Dimension [μm2] |

Monocrystal, non-insulator

> 20×20 |

The PC is where the samples will be prepared. An ion souce and a e-beam heater located in the manipulator allows the cleaning of single crystals using sputtering-annealing process. The quality of the samples can be checked by LEED optics installed in the chamber. The Manipulator is equiped by a 3 axes of translation and 1 axis of rotation, also has a cryostat for cooling samples using N2L for quantitative LEED experiments if necessary. In this same chamber, it is also possible to dose materials on substrates for the growth of ultra-thin films and growth of monolayers, which can be done by two e-beam evaporators attached to the chamber.

| Equipment | Parameter | Value |

|---|---|---|

| PREVAC manipulator | Motion

Heating [K] Cooling [K] |

6 axes

~ 300 – 1000 ~ 16 – 300 |

| LEED OCI-eletronics | Detector | MCP |

| Focus Evaporators | e-beam EFM 3

e-beam EFM 3T |

Single

Triple |

| Sample environmental | Pressure [mbar] | < 5×10-10 |

Samples are loaded into the system via the “load-lock”, which is pumped from atmospheric pressure to transfer pressure. Then, samples are transferred to a storage compartment in the IC chamber. This chamber has a UHV environment and a sample cleavage stage. Samples can be transferred to TC after they are cleaved and to MC aftwards, or they can be transferred from TC to PC if the preparation or growth of any material on the sample surface is required. The TC also has a sample storage compartment and as it has a better pressure than the IC, it preserves the preparation longer. It can also be used to store cleaved or prepared samples for a short period of time. In addition, it is essential for transferring samples from PC to MC.

| Chamber | Ambient/Pressure | Function |

|---|---|---|

| LL | HV/ 10-7 -10-8 mbar | Inserting samples into the system |

| IC | UHV/ < 5×10-9 mbar | Storage, cleaving samples |

| TC | UHV/ < 5×10-10 mbar | Storage, transferring samples |