Research obtains 3D images of catalysts under reaction by Bragg coherent X-ray diffraction

Catalysts are materials that promote and accelerate chemical reactions without being consumed during the process. For example, catalysts are used, for example, to reduce the emission of toxic gases, such as the carbon monoxide ($\rm CO$) produced by car engines. The catalytic converters present in the exhaust of vehicles allows the $\rm CO$ oxidation reaction to occur, that is, in the presence of a catalyst, $\rm CO$ reacts with the oxygen gas ($\rm O_2$) leading to the formation of carbon dioxide ($\rm CO_2$).

Hence, to achieve cheaper and more efficient processes to control vehicle pollution, a better understanding of catalytic materials is needed. Consequently, to carry out such challenging researches, the development of new scientific tools is constantly necessary.

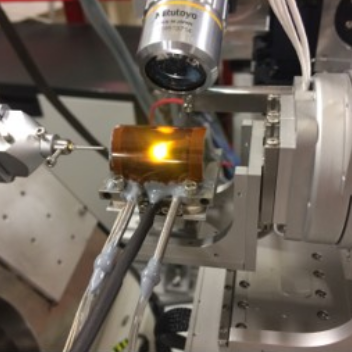

Hence, Amélie Rochet, a researcher at the Brazilian Synchrotron Light Laboratory (LNLS), and collaborators developed [1] a new reactor that allows the observation of catalysts in 3D under chemical reactions in a controlled gas and temperature environment (in situ conditions) with the experimental technique called Bragg coherent X-ray diffraction imaging.

The reactor was installed on the CRISTAL beamline of the SOLEIL synchrotron light source

The equipment was installed on the CRISTAL beamline of the SOLEIL synchrotron light source, in France, to study a catalyst composed of gold nanocrystals of 120 nanometers in size, supported on titanium dioxide ($\rm TiO_2$). Through the experiment made possible by the new catalytic reactor, the group obtained three-dimensional images of the gold nanocrystals with resolution of 32 nanometers during the chemical process of $\rm CO$ oxidation simulating the reaction conditions present in vehicle exhausts.

Thus, it was possible to show that the shape of the gold nanocrystals responds dynamically to the change in the gaseous environment: switching from inert gas to reactive gas mixture induces the transformation of the well-faceted nanoparticles into rounded nanoparticles. During the catalytic reaction, a reversible process occurs with a strong lattice displacement (movement of the atoms from the perfect crystalline structure) altering the structure of the active sites in which the reaction occurs.

In a near future, with the higher coherent X-ray flux that will be available in the new Brazilian synchrotron light source, Sirius, similar studies with much faster data acquisitions and unprecedented spatial resolutions will be possible.

Source: [1] Amélie Rochet, Ana Flávia Suzana, Aline R. Passos, Tiago Kalile, Felisa Berenguer, Celso V. Santilli, Sandra H. Pulcinelli, Florian Meneau, In situ reactor to image catalysts at work in three-dimensions by Bragg coherent X-ray diffraction, Catalysis Today, 2018. DOI: 10.1016/j.cattod.2018.12.020.

Research develops hydrogel from silk protein with potential application in photodynamic therapy

Results on its interaction with antibiotics may lead to the development of new forms of treatment for this disease